Research and Modelling of New Robots

by Using Innovative Technologies and Materials

1. Research plan and tasks to be executed by the research team

1.1. Description of the project's outline and work break down structure

WP1. Research activities related to the use of new materials, technologies and constructions in modern mobile robots. Synthesis and modelling of robots.

A study is being performed about new materials which can be applied in the construction of mobile robots. These may be materials that increase traction (or stick) between the feet of the robot and the ground. This increases the static stability of the robot and allows it to overcome steep inclines. Materials made by using nano technology and the like. Analyze the foreign experience.

Analyzes are performed about the specificities when using 3D printers to realize the nodes and models of robots. Various principles of 3D printing are being explored, the advantages and disadvantages are classified as well as the possibility for application in robotics. The realization of kinematic connections between the links can be done in a new way by using 3D printing. Suitable constructive solutions are selected. Analyzes are performed about the possibilities for the creation of links with very complex shape and its application in mobile robots. The previous experience of the team with this technology is used.

The current state of mobile robots designed to work in complex terrain to overcome stairs, climbing, inspection of pipelines and others is being studied .Typical representatives of robots inspired by biological analogies will be considered and also stationary robots used for educational and industrial goals. The classification will be done in a variety of features: The structure type of the robot, a method of moving, application and the like. The outstanding issues and possible ways to solve them will be outlined.

Algorithms for managing stationary and mobile robots capable of overcoming various types of obstacles are being researched.

The results are summarized and analyzed, classifications are made, the unsolved problems are selected and conclusions are drawn.

After analyzing the research done in selecting WP1, the most- promising approaches for synthesis and modeling of robots are selected. Based on these, new variants are generated presuming better qualities under certain conditions. The quality of the approved versions are studied on structural level, their advantages and disadvantages compared with other existing solutions are discussed. Part of the team is already working in this area and there are already developments in several areas part of which had adopted patent applications.

Will be optimized the basic geometric dimensions of the proposed robots and their nodes, so that to perform the functions required for a specific task assignments. This task is usually multivariate and with many possible solutions, which requires to clarify and specify the purposes for which to seek the optimal solution. A simplified 3D model of the robot is created. The possibility for simplified editing of the model is an important advantage in the search for the optimal design. This is achieved with the use of appropriate parametric models. The geometry of different links is controlled with appropriate local parameters, geometric relationships and functions. The mechanism as a whole and its configuration are controlled by global parameters. For open kinematic chains and part of the open-closed is convenient to control the parameters of the Denavit and Hartenberg. The environment in which the robot will operate is modeled in a similar manner. The aim is to create a model that best reflects the most characteristic features of the terrain, obstacles, manipulated objects and more. Here, the parameters are selected so that the environment can be easily reconfigured. Appropriate software is used to simulate the movements of the studied mechanisms, to reported collisions of the links during the movement and other geometrical parameters.

WP2.Theoretical and experimental study of the proposed structures. Conducting scientific seminars and exhibitions.

This activity can be conditionally divided into two stages:

Theoretical studies during the design stage - functional, kinematic, force analysis and optimization design.

Theoretical studies based on experiments and their results. Applying statistical, optimization and other methods for evaluating the results of the application of different materials, different applications of the 3D printing technology.

The first part is related to the theoretical determination of the basic kinematic and force characteristics of the robots. For this purpose will be used the vector-matrix approach and the method of Denavit and Hartenberg. Singular configurations will be determined after the analysis of the corresponding Jacobian matrices. An original physical interpretation of the properties of the Jacobian matrix will be applied, proposed.

This activity seeks to maximize the improvement of qualities of the studied robots. Different approaches will be applied for optimization of multi-purpose, poly-parametric tasks that are typical for robotics. It is included the analysis of specific structures and determining the target functions. Selection of suitable optimization algorithms.

The second stage is related to conducting experiments with the created prototypes. Different design solutions, control strategies and more will be tested. An interesting aspect is the application of new materials to build the feet of walking robots. For example, the use of the material gekskin - http://www.youtube.com/watch?v=9ZJYbcG0Ts0 (or similar) is expected to improve the quality of walking robots, thus they will overcome major slopes including movement on a vertical plane. Similar experiments will be conducted and analyzed.

Algorithms for controlling the robot are implemented and their behavior is tested in different situations. Parameters that serve to evaluate the characteristics of the robot are measured.

Sensor, control and actuator systems are tested in different situations.

Overcoming obstacles by the robots is experimented by varying part of their basic geometric parameters. The results are recorded in a table according to various criteria.

Sufficient number of experiments is carried out in order to make an objective assessment of the quality of the proposed design solutions, the applied materials and the new technology. Processing the obtained results. Conclusions, guidelines on the applicability of the developments in industry, service robotics and others.

WP3.Creating prototypes using 3D printing technology.

This activity envisages the creation of prototypes of the proposed in and structures, as well as promising new ideas.

- Creating precise 3D models and drawings.

By using the results from WP1 and WP2 final 3D models of the new robot are created. Structural elements shall comply with the used technology for 3D printing. It is created a technical documentation of the non-standard elements that are manufactured in a conventional manner.

- Selection and purchase of standard items

An analysis, selection and purchase of suitable actuators and transmissions are done. A selection of standard mechanical elements, sensors, electronic components, etc.

- Printing and adjusting of elements with the 3D printer. Assembling the structures.

Manufacturing of non-standard parts. After printing the elements are further developed if necessary - holes, threaded connections, etc.. Installation and testing of assemblies and components separately and as a whole.

- Models creating of the environment in which robots will operate.

Creating different models of obstacles and terrains in which to test mobile robots. These may be slopes, staircases, various branched pipelines and others. The dimensions of the models take into account the size of the robots. Part of this activity can be done with 3D printing, and the rest with conventional means.

- Adjustments - Corrections and remedying the problems in mechanical and electronic systems.

WP4.Design and implementation of appropriate control modules for the prototypes with elements of artificial intelligence.

Integrating sensors in the mobile robots, which provide adequate information to the control system in unstructured environments with obstacles, implies adequate analysis and differentiating the types of collisions in which the robot may fall when performing the tasks. This requires the review and analysis of similar constructions for robots, and when the movement is realized by on original structure it is required determination of the new combinations and the necessary hardware and software for the control system. The selection and development of the control system for some of the designed robots, in which there is a combination of passive and active degrees of freedom, is a specific task.

The realization of system for remote control of electromechanical devices is the object of the current task – prototypes of mobile robots by received data from brain bio-potentials.

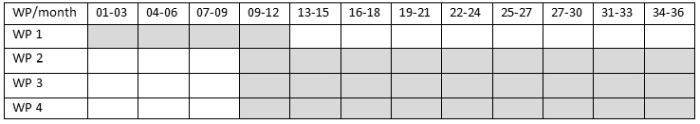

1.2. Schedule

Include Gantt diagram

1.3. Project management plan

The project management is carried out by the leaders of the team and accounting department of ISER - BAS and TU- Sofia. The schedule for implementation of the project should be respected.

The project is implemented by a consortium of two organizations: the Institute of System Engineering and Robotics - Bulgarian Academy of Sciences and the Technical University of Sofia. Coordinator and head of the project is Assoc. Prof. Dr. Iv.Chavdarov - Institute of Robotics (IR) - BAS.

Leaders of groups are:

- The group from IR - BAS – Assoc. Prof. Dr. Ivan Chavdarov;

- The group from TU – Sofia - Assoc. Prof. Dr. Roumen Trifonov;

The Financial resources will be distributed by the project coordinator, according to previously signed agreement.

Interim and final reports will be prepared by all participants (in the part that relates to the relevant unit) and the project coordinator will shape the summary report.

The organizational structure is chosen to serve the planned activities within the project. The implementation of the project activities is focused on the research groups into work packages and the activities are integrated.

The project coordinator supervise the implementation of activities and the respect of the planned project deadlines, responsible for preparing the internal rules for the project and the introduction management system, monitoring and control of project activities.

The leaders of working packedgs are responsible for the management and coordination of project activities. For each of the scientific tasks in the work program for the project there is WP Leader, who is responsible for the proper execution of the activities and the submission of results within the planned timeframe.